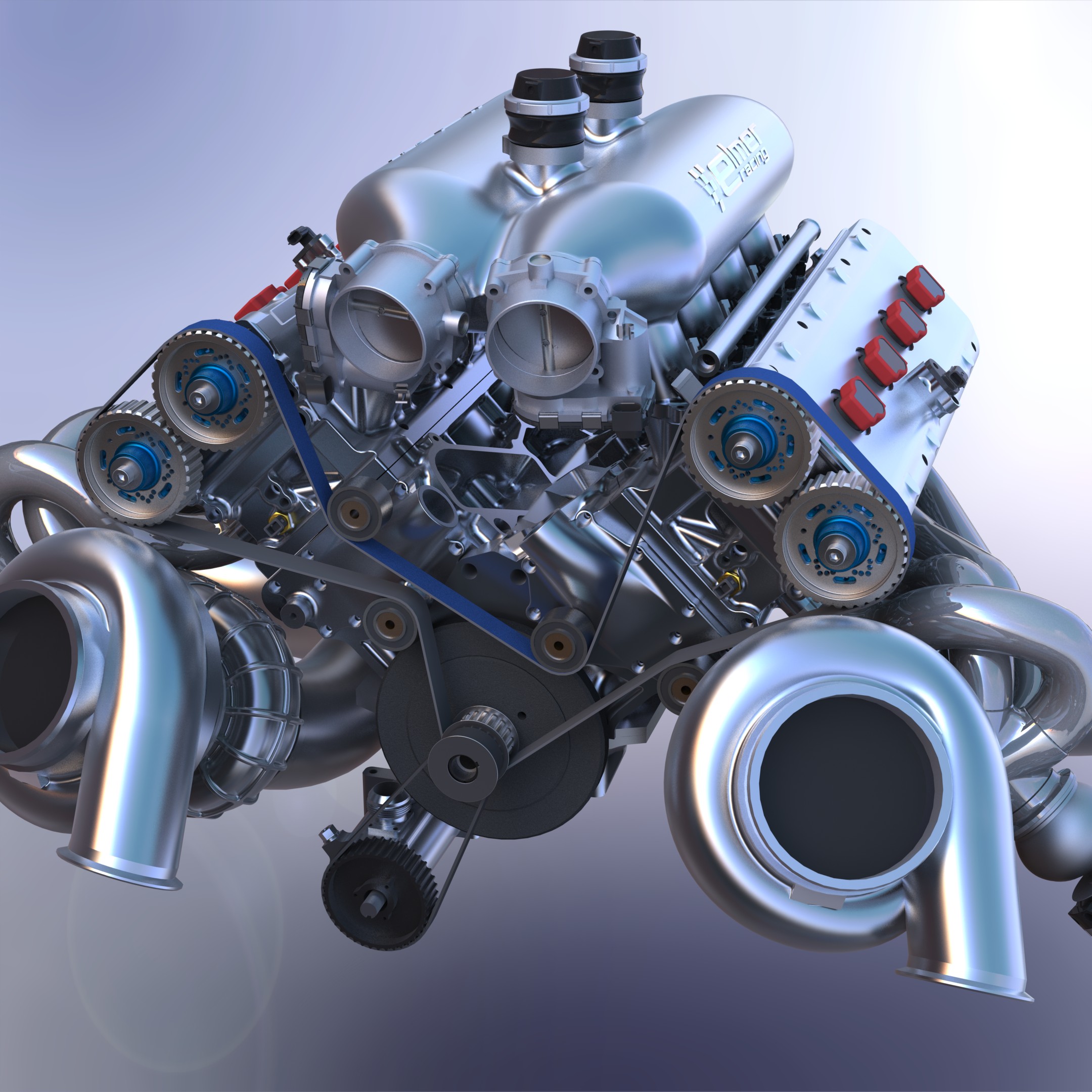

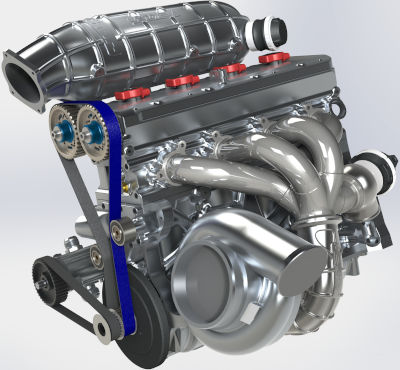

OEM Engine design and manufacturing

Custom engine design and manufacturing is our main focus at Elmer Racing. We're happy to work with customers that need anything from World Championship winning race engines, to emissions legal supercar engines, lightweight drone engines, and diesel tank engines.

We specialize in billet, fully cooled, lightweight, efficient, and compact engine designs and packages which suit a wide range of engines as above.

Our history is in extreme performance parts, like our full billet 4 time world champion #Thor racing engine, with the highest power-to-mass ratio of any OEM circuit racing engine ever! We also provide design and manufacturing support to other businesses for both racing and non-racing, series production and prototype/test engines.

Billet design and manufacturing

Billet Elmer Racing merge collectors

Our 304/304L stainless steel merge collectors are the most cost effective and durable options for turbo exhaust manifold manufacturing. So good in fact that they are also being used by customers on naturally aspirated engines! With over 250+ different designs available, we have most of your needs covered. Custom designs can be done also. Check our online RaceShop for some available examples!

Custom Billet components

We regularly help design and manufacture custom, complex shaped components for our customers. Intake manifolds with integrated bellmouths, flanges with built-in transitions, barrel throttle bodies, industrial components, and much more! We're setup to be able to provide these services for a wide range of materials, hardened tool steel, magnesium, aluminum, stainless steel, we even machine wood and plastics for special orders.

Check out our online RaceShop, for some ideas of the kind of custom products we can make!

- Details

RP968 and Thor!

To celebrate this unprecedented achievement with everyone, we're offering a 40% discount on new Thor orders! That's 10% per world championship!

It has never been cheaper to get a lightweight 2000hp engine for your race car! But lets take a quick look at

- Details

Móði is here! Our "bolt-in" replacement engine for the Mitsubishi Evo X 4B11T. Dry sump, 1000+hp, billet head and block, anti-lag ready, this has it all!

- Details

This is Magni! Our "boring division's" 6000hp concept V8 engine based on Thor!

- Details